Whether you’re developing the next commercial aircraft or building components for a deep-space mission, the challenges of aerospace engineering are immense. Engineers must design systems that can endure extreme environments high speeds, fluctuating pressures, intense heat, and mechanical vibration. Meeting these demands means making smart, informed design decisions early in the process.

At SDA Software, we help aerospace and aviation engineers solve real problems with the right simulation software. Our recommended solutions integrate Finite Element Analysis (FEA) software, Computational Fluid Dynamics (CFD) software, and advanced meshing capabilities into a unified workflow.

What’s the Best FEM Software for Aircraft Stress Analysis?

Finite Element Method (FEM) software helps engineers simulate how parts behave under mechanical, thermal, and dynamic loads. In aerospace, where weight, durability, and reliability are non-negotiable, this type of analysis is foundational.

Simcenter Femap is a widely used Finite Element Analysis software tool that:

- Simulates stress, deformation, vibration, and fatigue

- Models bonded structures, composites, and assemblies

- Integrates with Nastran solvers for accurate results

With Femap, engineers evaluate design options early, reducing the need for physical prototypes. It’s CAD-neutral, mesh-centric, and built to handle the complexity of aerospace assemblies

How Does Mesh Quality Affect Simulation Accuracy?

Meshing transforms geometry into a finite model that can be simulated. In aerospace, where precision matters, high-quality meshing is critical.

Siemens Simcenter’s meshing software offers:

- Local refinement for stress concentrations

- Control over element shapes and transitions

- Boundary layer tools for fluid-solid interfaces

Adaptive meshing lets engineers capture sharp gradients without unnecessary computational cost. It’s not just about having a mesh it’s about having the right mesh.

Can CFD Software Model Supersonic Airflow and Heat Transfer in Engines?

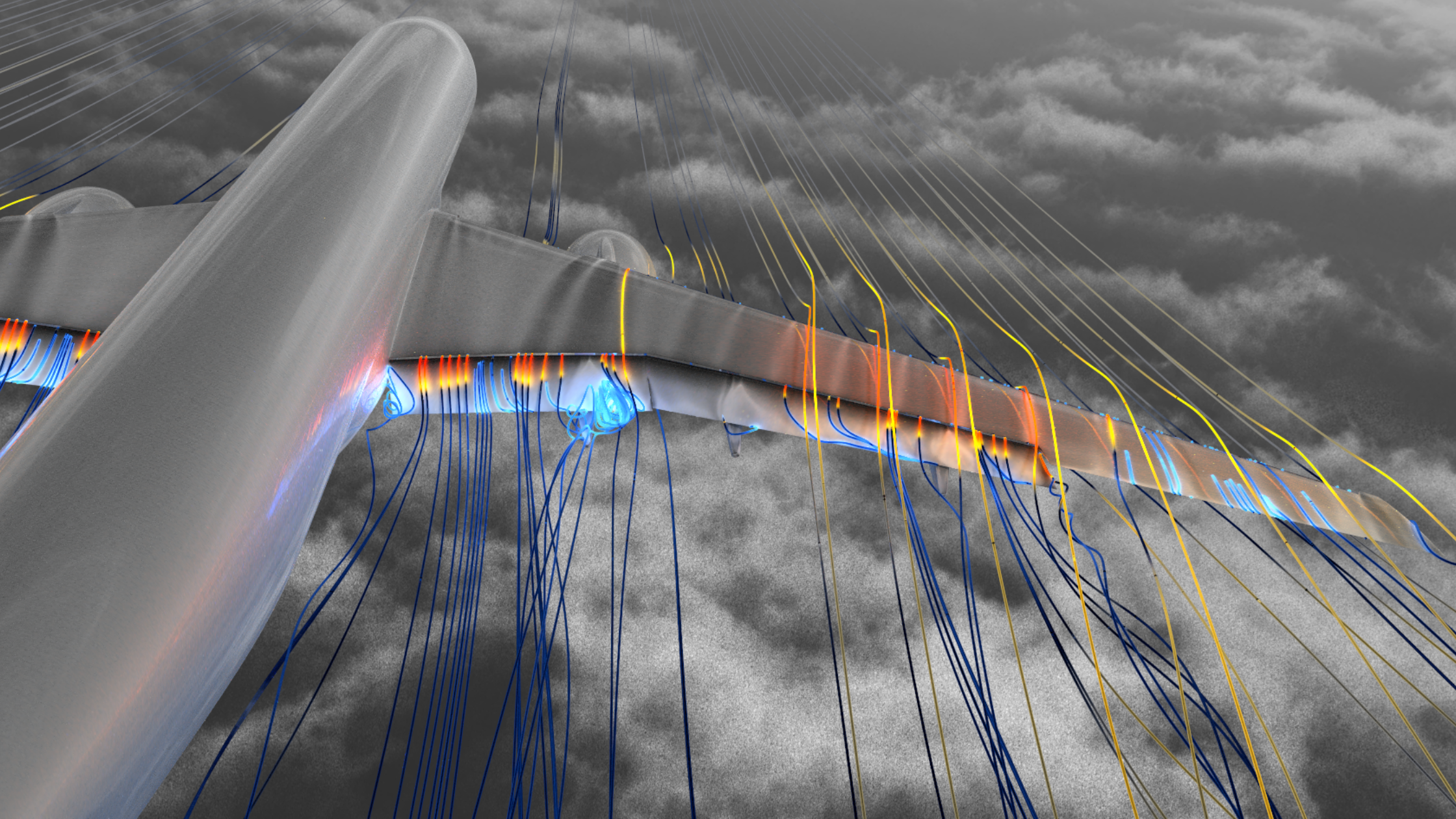

From lift and drag to fuel flow and cooling, fluid behavior plays a major role in aerospace systems. Computational Fluid Dynamics software helps engineers model these behaviors before wind tunnel or thermal testing.

Simcenter STAR-CCM+ from Siemens supports:

- Compressible and incompressible flows

- Conjugate heat transfer and thermal management

- Turbulence, shock waves, and multiphase flow

CFD simulations help aerospace teams understand airflow around wings, heat buildup in enclosures, and the effect of flow separation. STAR-CCM+ handles complex geometries and integrates with structural tools for fluid-structure interaction.

How Do I Simulate Fluid-Structure Interaction in Aerospace Design?

Most real-world aerospace problems span multiple domains:

- Aerodynamic loads affect structural performance.

- Heat from engines changes material behavior.

- Vibrations from airflow impact electronics.

With Siemens’ integrated environment, engineers can:

- Pass pressure and temperature fields from CFD to FEM

- Automate multi-step workflows

- Maintain geometry and mesh continuity across tools

This multiphysics approach reflects the real-world behavior of systems. It leads to better predictions and better designs.

How Do I Reduce Physical Prototypes Using Simulation?

A simulation-driven process might look like this:

- CFD models external airflow across the wing.

- The resulting pressure map is transferred to the structural model.

- FEM software calculates deflection, stress, and potential fatigue.

- Thermal analysis evaluates material response across altitudes.

- Engineers refine the design before physical testing.

This integrated process saves time, reduces cost, and improves confidence.

Which Siemens Software Is Best for Aerospace Simulation?

SDA Software is more than a software reseller. We’re engineers supporting engineers—with hands-on experience in:

- Structural and thermal simulation

- Composite materials

- Fluid-structure interaction

We specialize in Siemens tools, including Simcenter Femap, STAR-CCM+, NX CAD, and Teamcenter. We provide training, support, and simulation strategy consulting.

Whether you need help setting up models, validating workflows, or scaling your analysis, we can help.

Final Thoughts

Simulation isn’t about replacing physical testing it’s about knowing more before you build. With FEM software, CFD software, and meshing tools, aerospace teams gain clarity, reduce rework, and deliver better products faster.

Need answers to tough engineering questions?

Let’s find the right tools and workflows together. Contact SDA Software to start building your simulation strategy.